Summary: This

review has important information for anyone who is thinking about building the

oneTeslaTS Tesla coil kit. It can

be done, but it is a very challenging project. Helpful work-arounds for difficult steps in the project

assembly are described, and omissions or confusing parts of the manual are

explained.

When a company markets a product kit for the

"experienced" do-it-yourselfer, you can expect a few bumps along the

road. After all, meeting

challenges and overcoming them is part of what doing it yourself is all

about. The oneTeslaTS (the big

kit—not the tinyTesla, which is a separate product) promises to make sparks up

to 20 inches (50 cm) long. At a

cost of $400, this is a serious commitment, but it is much less expensive than

other commercially built Tesla coils, which cost in the multi-kilobuck

range. Partly for research

purposes, and partly out of curiosity to see how the oneTesla folks had pulled

this off, this reviewer ordered the kit (plus a set of spare parts), and it

arrived a few days after Christmas.

First, a brief summary of my qualifications to critique a

design like this. I teach

electrical engineering at Texas State University, San Marcos, Texas. I have a BS from CalTech, an M. Eng.

from Cornell, and a Ph. D. from the University of Texas. I built my first Tesla coil when I was

about 12 (with a college-age neighbor) back in the 1960s. About a decade ago, a colleague of mine teamed with me on building

a second Tesla coil from scratch, a unit I still use in

research. Last year I published a

textbook, Analog and Mixed-Signal

Electronics (Wiley, 2015). So

I think I am qualified to render an opinion on the quality of the circuit

design, the manual, and the experience of building the kit.

To cut to the chase:

My oneTeslaTS works, but I ended up having to modify certain steps in

the assembly and do some rewiring to get it to work at all. And my particular unit had a recurrent

problem that was remedied only by replacing the main board. First, a word about the good features

of the design.

Good News: Small and Straightforward

The oneTeslaTS is specifically a double-resonant solid-state

Tesla coil (DRSSTC). Solid-state

simply means that the high-frequency AC power that is transformed up by the

transformer at the heart of the unit, is produced by transistors instead of by

old-fashioned (noisy, inefficient) spark gaps, which is what my first 1960s

Tesla coil used, and is what some of the true monsters of the Tesla-coil world

still use. Double-resonant means

that there are two tuned circuits, one involving the primary coil and one

involving the secondary coil, and the thing works by putting energy into the

primary and then letting the mutual coupling between the coils transfer the

energy to the secondary at a much higher voltage. For further explanations of any technical stuff here, see

the Legacy Gen1 manual on the oneTesla website at http://onetesla.com/oneTesla_User_Manual_v1.3.6.pdf. That manual is for an earlier

discontinued model, but does a much better job of explaining how a Tesla coil

works than the newer model's manual (http://www.onetesla.com/oneTeslaTS_User_Manual.pdf).

One of many challenges faced by the oneTeslaTS designers was

how to squeeze a high-performance Tesla coil, able to put out in excess of

200,000 volts (200 kV), into a small package, less than a foot (30.5 cm)

tall. Most DRSSTCs are at

least twice that tall to allow room for the thousands of turns of fine wire

wound in a single layer on the long high-voltage secondary coil. More turns means more voltage, and so

obtaining 200 kV from a primary coil excited by 340 VDC (which is all you can

get from a full-wave rectifier operated directly from the 120-VAC mains supply

in the U. S.) requires lots of turns of wire.

The way the oneTesla people squeezed all those turns into a

coil less than 8 inches (20 cm) long is by using fine wire. Very

fine wire. No. 38.5, according

to the oneTesla manual. That's

about 0.1 mm, less than the diameter of a human hair.

The only places such fine wire is used routinely that I'm

familiar with is in earphones and the old-fashioned "D'Arsonval"

analog meter movements. But such

things require close to watchmaker precision and steadiness of hand to

build. Can an average kit-builder

deal with wire that fine? We'll

talk about that later. Suffice it

to say that with such fine wire, the designers got enough turns in their

secondary to make sparks that rival other units that are twice or three times

the physical size of this one.

Another clever trick was to make the primary coil a

circuit-board pattern, etched directly into a two-sided board on which the

secondary is mounted. This

eliminates any need to hand-wind or insulate a primary coil, which the oneTesla's

earlier (Gen1) model required. It's

also probably cheaper than a long hunk of solid wire.

The driver electronics also has some nice features. It's controlled (or supposed to be

controlled—see below) by an "interrupter board" which is at the other

end of a ten-foot fiber-optic cable.

This cable is just a piece of plastic and will not interfere with or

pick up the strong electric field coming from the operating Tesla coil. I learned about this the hard way when

I tried to control my previous research Tesla coil with a coaxial copper cable. The first time I tried it, induced

currents fried the electronics, and after that I switched to fiber-optic

control, which has caused no problems.

The other problem solved by the driver electronics is

tuning. Like two tuning forks set

at the same pitch, the primary coil and the secondary coil have to resonate

("ring") at or near the same frequency for good energy transfer. And the driver electronics has to send

that frequency to the primary or else the driver can't work well and may burn

up. The oneTeslaTS circuit is

basically a feedback loop that senses the current in the primary and

automatically tunes its frequency to the resonance frequency of the

system. This is a clever solution

that avoids a lot of fussy manual tuning that other systems require.

Small, efficient, easy to build—what could go wrong? Well, quite a few things,

actually. But not until I got past

the circuit-board assembly steps, which are by and large straightforward,

accurate, and not that hard to do if you know how to solder, how to read

resistor color codes, and how to follow instructions. The interrupter went together without a hitch, but I was

left clueless by the manual as to how to operate it.

The main circuit board passed its low-power test, making a satisfying

buzz when the interrupter was connected to it. The next step was completing the secondary coil. Fortunately, the kit comes with a

completely wound secondary, but it's just a coil: a plastic tube with several thousand turns of wire on

it. It's your job to insulate it

better and put end caps on it.

Not So Good News

Five Ways To Break No.

38.5 Wire

I was well aware that the quality of the secondary coil

would determine the quality of the unit, so I was careful to follow the

instructions about how to treat it.

The secondary is supplied "bare" (only the

insulated wire on it) and it's the kit-builder's job to apply enough insulation

on the winding itself to keep it from breaking down under the extreme stress of

holding off some 200 kV across only a few inches of space. The manual says to "varnish"

the secondary, and shows a picture of one next to spray cans of Krylon Crystal

Clear acrylic coating, and Minwax Helmsman spar urethane. There was some comment in the manual about

substituting packing tape, but the important thing is to surround each turn of

wire with a dielectric (insulator) that works a lot better than plain air. I decided to set up a rig (Fig. 1)

Fig. 1. Coil-varnishing rig.

on my workbench that would slowly rotate the coil about a

horizontal axis at a few RPM. I

had a geared DC motor lying around, but an old AC motor from a rotisserie

barbecue set would work. I cut a

couple of pieces of cardboard out to make rings that would just fit inside the

coil and around the broomstick axle to support the coil on the axle. The idea is to keep the spray from

sliding to the lowest part of the coil and beading up due to gravity. The manual said to put at least five

coats on, and I used five coats of the Minwax Helmsman brand spar urethane, moving the spray

evenly back and forth as the coil turned and spacing the coats apart by about

an hour. After letting it dry

overnight, the resulting finish was very smooth and thick enough that I have no

hesitation in grabbing the middle of the coil and picking the unit up that

way. Don't try this with the bare

coil—you'll probably break something and have to order a new one.

The next major operation on the secondary was to assemble

the end caps. The whole point of

the end caps is to insulate the two ends of the coil from each other as much as

possible, because those two ends are where the 200 kV shows up. My coil was supplied with several

inches of wire at each end, and nothing specific was said in the manual about

how much of this wire to use or how long to make it before you assemble the end

caps.

HERE IS THE FIRST SUPPLEMENT I recommend to the manual. Cut off all the wire from both ends

except what you HAVE to use to make the end caps fit. That is probably about 40 or 50 mm, depending on how you

assembled your end caps.

The end caps are stacks of clear insulating plastic

laser-cut in various patterns to form a totally enclosed cavity where a ring

terminal makes a connection between a bolt going through the middle, and the

end of the wire adjacent to the cap.

The manual recommends assembling the caps using HOT GLUE, NOT EPOXY. I TOTALLY AGREE, because it

took me five tries to get the bottom end cap together. I broke the wire the first four times. If the layers of the end caps are not

almost EXACTLY coaxial (all their outside edges perfectly in line), the end cap

will not fit into the inner diameter of the secondary tube and you will have to

pry the thing apart. My wife (who

is familiar with hot glue) recommended putting the stack in the freezer for 15

minutes or so to make the hot glue more brittle and easily broken up. This worked great, but I still had to

take a sharp razor or Xacto knife and scrape all the old glue off before lining

things up for the new glue.

As a participant in the oneTesla forum noted, the existing

end cap design sort of makes a pair of scissors that tend to cut the wire right

where it leaves the top of the tube and runs down between the inside of the

tube and the end cap layers to get to the ring terminal, where you have

carefully soldered it. Fig. 2 is a

picture (adapted from the oneTesla v. 1.4 manual) of how they want you to

assemble an end cap:

Fig. 2. Manufacturer's recommended way of

connecting secondary wire to end cap.

In order to do this successfully, you must (a) solder the

fine wire from the coil to the "ring terminal" (I call it a solder

lug) that goes around the bolt, (b) while holding the entire assembly out of

the top of the coil, but near enough not to stretch or break the wire, finish

assembling the top pieces of the end cap together, and (c) slide the entire end

cap assembly into the coil WITH THE WIRE ATTACHED, WITHOUT BREAKING THE WIRE.

This is very hard.

After five tries, I managed this on the bottom terminal, but

one failure on the top terminal convinced me to come up with a better way,

which leads to this: HERE IS THE

SECOND SUPPLEMENT I recommend to the manual.

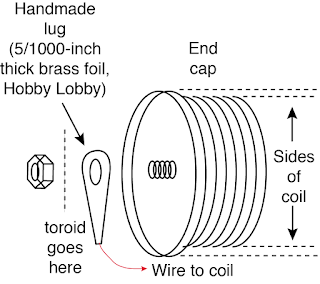

Instead of

trying to connect the wire to the ring terminal, either save it out before you

assemble the end cap, or make your own out of 5-1000ths of an inch thick solderable brass or copper "foil"

(available at hobby shops like Hobby Lobby), as shown in Fig. 3:

Fig. 3. My way of connecting secondary wire to

end cap.

I simply soldered the wire at the top end to my hand-made

brass ring terminal (cut out with a pair of scissors), and screwed the toroid

and the retaining bolt down on top of it all. (If you save out the ring terminal when you assemble the end

cap, you won't have to roll your own.)

This is vastly easier than first connecting the wire to the terminal

inside the end cap, and then trying to fit the whole thing, with the wire

attached, into the coil. My way,

you can put the end cap on first, and then lay the terminal on top of the bolt

and put the toroid on it.

While the original end cap design does a good job of

insulating the wire and the ring terminal all around, there is no need to

insulate them from the toroid (on the top) or the ground plane (on the bottom),

because the wire is directly connected to those points anyway. My point is that placing the ring

terminal (or a substitute) directly on the end cap surface should not cause any

insulation worries, and so far my modifications in this department have not

caused any issues. There is still

plenty of end-cap insulation where it counts (between the top and bottom

wires), and as long as you keep the wires well away from the hollow part of the

inside of the secondary tube, you should not have a problem in this department,

as some unfortunate kit-builders

have run into. But maybe they

didn't know what to do with all that extra wire, so they left it dangling

inside the secondary tube. No, no,

no.

Blowing the First Fuse

One of the tie points for the power connector is very close

to one of the tie points for R5, one of the high-voltage power supply bleeder

resistors that discharge the high-voltage filter capacitors to keep you from

killing yourself when you take your kit apart to fix it (as you surely

will—take it apart, I mean, not kill yourself). So leaving that resistor off is not an option. But I was not the only person

accidentally to leave a solder bridge between the resistor and one of the AC

terminals of the bridge rectifier.

The result was that when I followed the instructions for the first

startup and plugged it in, I saw a bright green flash from somewhere on the

circuit board and that was that.

The solder bridge had not only blown the fuse, but had vaporized a

section of circuit-board trace (vaporized copper glows green, in case you're

wondering). Subsequent waiting and

inspection revealed the problem, and a trip to Radio Shack (yes, there's a few

left) laid in a supply of 10-amp fast-blow fuses of the right physical

dimensions. Be sure and buy or

order at least a dozen of those before you start running your unit. It's also a good idea to order at least

one set of four replacement IGBTs, which oneTesla offers as an option.

This was the last major problem that I can say was

definitely attributable to me. The

following issues have more subtle causes that took a few more weeks to resolve.

Eating IGBTs

Here is the way this device is supposed to work. The interrupter board generates light

pulses that occur at a frequency (number of pulses per second) determined by

the "frequency" setting of the board. Just for the record, and for the convenience of everybody

who wants to use the "SD" interrupter board, here is THE THIRD

SUPPLEMENT I recommend to the manual:

a flow chart for the interrupter board controls.

Controls: main

power (slide switch on left side of enclosure), LCD display illumination (slide

switch above LCD display), "select" (*) (middle pushbutton),

"up" (^) (top pushbutton), and "down" (v) (bottom

pushbutton). User operations are

*, ^, or v.

Condition: No

SD card inserted.

Main power ON (LCD display on or off, doesn't matter):

>"Checking SD Card"

>"Fixed Mode"

*

>"[Freq:

20Hz ]"

The unit is now producing a 13.6-microsecond pulse at a

frequency of 20 Hz. The pulse

frequency can be adjusted upward to a maximum of 1000 Hz (1 kHz) by pressing

and holding the ^ button, and lowered down to 1 Hz (the minimum) with the v

button.

At any given frequency, the duration ("dwell time") of the pulse can be lengthened by

pressing * again:

This moves the pair of brackets [] from the top display line

to the bottom display line. Now,

the user can increase the pulse duration ("power") by pressing the ^

or v buttons. The longer durations

are indicated by dark rectangles extending across the bottom of the screen

display, up to a maximum of 14 rectangles.

By direct measurement of the pulse duration in my lab, the

minimum pulse duration (lowest "power") at all frequencies is 13.6

microseconds. The maximum pulse

duration varies from 48.6 microseconds at 1 Hz to 25.6 microseconds at 1

kHz. The longer pulses are needed

at lower frequencies, apparently to even out the loudness at different

rates. The fact that the maximum

pulse duration occurs at the lowest pulse frequency probably explains the

rather cryptic statement in the manual that "higher frequencies draw less

power from the coil." This is

true if you have run your interrupter power level higher than the minimum.

If you haven't figured it out by now, the longer the

interrupter is HI (on), the more cycles of 260-or-so kHz power the driver will

pump into the primary, and the more energy will come out the top of the

secondary. At some point the

voltage on the secondary coil will be high enough at the tip of the breakout

point (the brass wire supplied with the kit that is shown sticking out

horizontally from the toroid), and the energy will start to dissipate into the

air. The discharge at the tip of

the breakout point starts as what plasma physicists call

"corona": a burst of

tiny fast cold spark-like feathery discharges that absorb some energy and turn

it into heat, light, and some chemical reactions (this is where the ozone smell

comes from).

Fig. 4. Video of first test of oneTeslaTS.

Although the interrupter was set to low power

(short-duration pulse), what I saw in that video did not look like any low

power to me. After unplugging the

unit and waiting a suitable time (at least five minutes) for the power

capacitors to discharge, I disassembled it and checked the IGBTs. They had failed, and so had the 10-amp

fuse.

How did I know

they failed? Using the "diode

check" function of a DVM, a good IGBT will show about 0.4 V when the

collector is negative and the emitter is positive, and open with the opposite

polarity. (See the IGBT data

sheet, available online at https://www.fairchildsemi.com/products/discretes/igbts/discrete-igbts/FGA60N65SMD.html for pinouts). When the device fails, usually a short

circuit appears between these two terminals, with either polarity.

I highly recommend (as the manual does)

leaving the full lead length of the IGBTs sticking up from the board when you

replace them, because these leads form convenient test points to contact with

DVM leads without taking the board stack apart. Be very careful to place the sil-pads correctly, because any

electrical contact between the IGBT's

metal case and the heat sink will in all

likelihood blow a hole in your heat sink and

possibly turn the IGBT into a small bomb,

too. (This is on the user's forum

as well, once

you register.

You can't see everything until you register.)

I was somewhat mystified by the pretty catastrophic failure

of both transistors and the fuse, despite my precautions of starting with the

lowest power setting on the interrupter. The way the oneTeslaTS is designed, it

is not possible to operate the IGBTs at any voltage lower than 320 V or

whatever the voltage-doubler power supply creates from your local power

line. Even with the

lowest-duration pulse, this is asking the IGBTs to do a lot if something

happens to make the pulse a lot longer than minimum. And it turns out, that was exactly what was happening.

In one chapter of my book, I discuss a fairly obscure

topic: EMI, which stands for

"electromagnetic interference."

EMI is what happens when somebody's cellphone starts bothering an

auditorium's PA system, for example.

It is unintentional coupling of a signal to a circuit by means of

electric, magnetic, or electromagnetic fields.

After about four days of trying to get my oneTeslaTS to work

at home, I went through two sets of IGBTs, an equal number of fuses, and was no

closer to a solution. I could not

understand why even though I set the interrupter to a specific frequency, the

sparks would emerge from the breakout point in loud random pops until something

busted. Finally, after modifying the unit to apply less than full

voltage to the IGBTs and observing its output with an oscilloscope, I

determined the problem: loss of

control by the interrupter.

Loss of Interrupter

Control

By using a variable AC supply device called a variable

autotransformer (tradename "variac"), I slowly increased the voltage

on the IGBTs, slow enough so that when the bad thing happened, they would not

be working under the full stress of 340 V and might not immediately fail. (This was after I connected the driver

power supply to a separate constant 120VAC source so that it could operate

normally regardless of the IGBT supply voltage.) Up to about half voltage, I saw that the system was behaving

properly. The interrupter was

signaling the driver to allow oscillation for a few cycles, and the secondary

was putting out high-voltage pulses exactly in time with the interrupter

pulses. Then at about 55% of full voltage, POP! I saw the scope screen fill with a constant oscillation,

much longer than the interrupter would allow it to do if it was still

controlling the system. Somehow,

the high electric field from the secondary was getting back into the

electronics and keeping the oscillations going even AFTER the interrupter

"told" it to quit.

Here in Fig. 5 is a captured pop from a Tektronix TDS2014B

scope with its probe picking up an arbitrary-scale electric field (vertical

axis) and the timebase in milliseconds (horizontal axis):

Fig. 5. Electric field (arbitrary units) from

Tesla coil during a "pop."

Time axis units are milliseconds.

This explained my problem. The IGBTs are not capable of operating continuously at 340 V

supplying full power to the secondary.

After a few milliseconds of what amounts to a VERY high-power pulse,

they heat up so much that they cease to switch efficiently, the field falls, and

the EMI loop is broken. The pulse

quits, but the IGBTs are so hot that the system can no longer oscillate

normally for a short time. Then it

recovers, runs under interrupter control for a time, the field builds up again,

and POP! the cycle repeats. This is somewhat speculative, but explains the data.

If I had increased the IGBT voltage to full (100%, 340 V)

they would undoubtedly have failed again the next time the interrupter lost

control.

How is this thing to be prevented? Commercial and hand-crafted Tesla coils usually have

elaborate electrostatic metal shielding around the control electronics. There is no cheap shortcut to good

shielding, so this is why they cost so much. My first thought was to put on the side panels in hopes that

they would provide enough shielding to stop the loss of interrupter control

(POPS for short). But alas! the

manual's statement that "installing the cosmetic side panels is

optional" turned out to be true.

They are largely cosmetic and did not provide enough shielding to fix my

POP problem.

At this point, I turned to the user forum hosted by oneTesla

on their website. I wrote a

detailed post describing my problem, and after a few days received a short

reply from

Bayley (the "lord protector"), saying it sounded

like a grounding problem. I

rechecked grounds and found nothing obviously wrong, so eventually I resolved

to replace the entire main board.

This costs about $80.

Fortunately, exchanging main boards is pretty straightforward, mostly a

matter of lining up a new set of IGBTs and disassembling and reassembling the

board stack.

Fig. 6.

Electric field (arbitrary units) during one interrupter pulse from

proper operation of oneTeslaTS.

Time axis units are microseconds.

Parting Words

If you are careful to avoid solder bridges, do a good job of

varnishing the secondary, and make connections to the secondary on the outside

of the end caps instead of the way recommended by the manual, you could

conceivably have the oneTeslaTS up and running in a week of working on it a

couple of hours an evening. I was

not so lucky.

Although I haven't

used the MIDI feature, the interrupter takes a memory card with a MIDI file on

it, and so the tunes you can play on the thing are limited only by your stock

of MIDI-file tunes (there are five on the oneTesla site to get you going). Especially if you haven't done this

kind of thing before, building this kit will be a learning experience. But don't start unless you're prepared

to devote a lot of time and thought to this project, and a fair amount of filling

in the blanks left by the overly brief instruction manual.

REVIEW POLICY NOTICE: I paid for the

above-described kit myself and have no connection with oneTesla or its

employees. I will not review other

kits by request, and will turn down any such requests.

Karl Stephan

Feb. 3, 2016

See my blog on

engineering in the news at